In the era of dynamically evolving industrial technologies, where automation, edge computing, and real-time data analysis are becoming the foundation of manufacturing, industrial personal computers (IPCs) play the role of a central integration hub. Between the second and third quarters of 2025, we are observing a clear shift towards modular IPC designs, mounted on a DIN rail. These two elements – flexible, configurable construction and fast, standard mounting – are collectively becoming the new standard in the industrial sector.

What is a DIN-rail industrial computer and what does modularity mean?

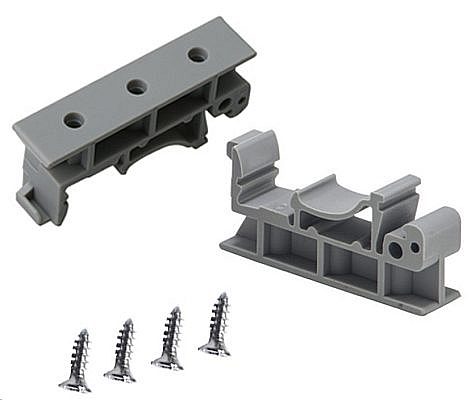

A DIN rail is a standard metal rail (usually 35 mm wide) used for mounting electrical devices and automation equipment in control cabinets. Industrial computers that comply with this mounting standard offer great installation convenience, especially in industrial environments where space, compatibility, and durability are key.

Modular IPCs allow for:

- expansion with additional modules (e.g., AI, GPU, Wi-Fi, 5G),

- easy replacement of components (ports, memory, interfaces),

- customization of the set for specific applications.

This means that one type of computer can be scaled and modified for different projects without the need to replace the entire system.

Market Trends in Q3 2025

Modularity as the foundation of flexible manufacturing

Manufacturers like Advantech, Cincoze, Beckhoff, Nexcom, and Kontron are focusing on creating platforms that can be easily adapted to the changing needs of manufacturing plants, logistics, rail transport, energy, and critical infrastructure.

Modern modular IPCs offer:

- slots for PCIe and mini PCI expansion cards,

- M.2 slots for NVMe drives and communication modules,

- I/O extensions – RS-232/485, USB, CAN, GPIO,

- integrated passive cooling systems.

DIN-rail – not just mounting, but an integration standard

The DIN rail is no longer just a convenient mounting method. Thanks to its unification:

- it enables quick replacement of units in distributed systems,

- it reduces the time and cost of installing devices,

- it allows for the standardization of control cabinets in various facilities.

Compliance with standards (e.g., IEC 60715) and collaboration with components like PLCs, HMIs, relays, and circuit breakers make DIN-rail IPCs the central point of a modern automation cabinet.

Benefits of modularity and DIN-rail mounting

- Scalability: One hardware platform can handle multiple applications – from a simple data logger to the heart of a SCADA system with AI.

- Space-saving: Compact dimensions make installation easy even in small control cabinets.

- Ease of maintenance: Modularity allows for the replacement of only a damaged section without interfering with the entire system.

- Future-proofing: The ability to expand the hardware in the future – e.g., adding an AI card or 5G communication.

- Standardization of deployments: IPCs can be pre-configured and quickly installed in various locations.

|

|

Integration with modern technologies

Today, modular DIN-rail IPCs are the basic infrastructure for:

- Edge computing: local data processing near machines (e.g., from sensors or cameras),

- AI on the edge: thanks to GPU modules, it is possible to analyze images, detect anomalies, and perform predictive control,

- Time-Sensitive Networking (TSN): new IPCs support ultra-low latency industrial networks,

- 5G/TSN/Wi-Fi 7: built-in wireless interfaces give IPCs communication flexibility.

Applications

- Manufacturing – integration with robotic lines, monitoring machine operating parameters

- Railways – resistance to shock, temperature, EN50155 standards

- Energy – remote supervision of transformer stations, SCADA systems

- Logistics – AMR control, real-time warehouse management

- Smart City – lighting control, infrastructure monitoring

Modularity and DIN-rail mounting are not a passing trend but a strategic response to the challenges of modern industry. Flexible, scalable, energy-efficient, and easy to integrate industrial computers are becoming the new backbone of digital transformation.

In the face of growing demands for data processing, reliability, and flexibility, industrial organizations are choosing solutions that grow with their needs – and that is exactly what modular DIN-rail IPCs provide.