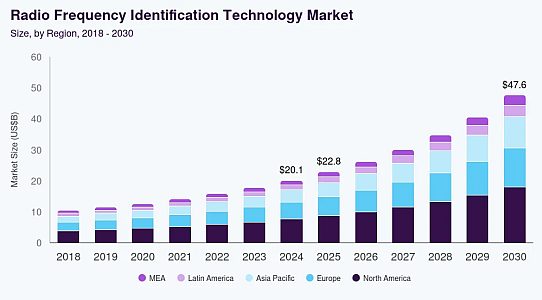

RFID (Radio Frequency Identification) is a key technology enabling automated identification, tracking, and data collection across industry, transport, retail, healthcare, and everyday life.

- History and evolution of RFID technology

- Industrial, logistics, and transport applications

- Benefits for inventory control and asset tracking

- Use in homes, sports, and healthcare

- Future trends and integration with IoT and AI

Introduction to RFID Technology

RFID, or Radio Frequency Identification, is a technology that enables the wireless identification and tracking of objects, people, and assets using radio waves. Unlike traditional barcode systems that require direct line-of-sight scanning, RFID systems can identify items automatically, at a distance, and often simultaneously. This capability has transformed how organizations manage inventory, logistics, security, healthcare, and many aspects of everyday life.

Today, RFID is considered a foundational technology for Industry 4.0, the Internet of Things (IoT), and smart automation. However, its origins date back much further than most people realize.

The History of RFID: From Military Roots to Global Adoption

Early Beginnings: RFID Before It Had a Name

The conceptual foundations of RFID emerged during World War II. One of the earliest practical implementations was the Identification Friend or Foe (IFF) system developed by the British military. Radar signals were transmitted to aircraft, and friendly planes responded with a radio signal, allowing operators to distinguish allies from enemies.

Although primitive compared to modern standards, this system demonstrated the core principle of RFID: wireless identification using radio waves.

Post-War Research and Commercial Experiments

In the 1950s and 1960s, academic researchers began exploring radio-based identification systems. The first RFID patents appeared in the 1970s, focusing on electronic article surveillance (EAS) for theft prevention in retail stores. These early systems were simple, typically using passive tags that triggered alarms when removed from protected areas.

RFID in the Late 20th Century

During the 1980s and 1990s, RFID technology matured significantly. Improvements in semiconductor manufacturing made tags smaller, cheaper, and more reliable. Governments began using RFID for applications such as:

- Vehicle identification and toll collection

- Animal tracking in agriculture

- Access control for secure facilities

By the late 1990s, large corporations and logistics providers started experimenting with RFID to improve supply chain visibility.

How RFID Works: Core Components and Principles

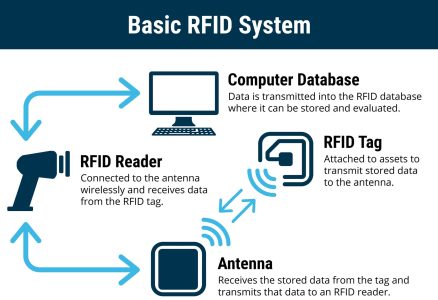

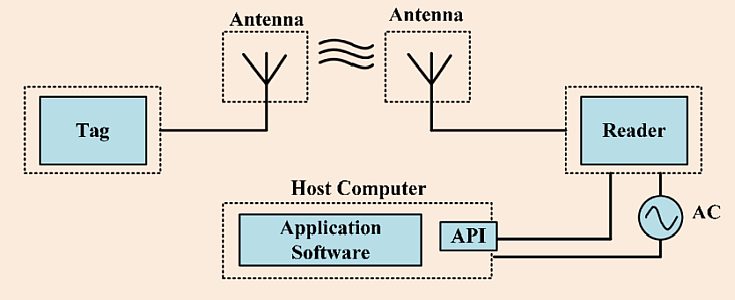

Key Components of an RFID System

A typical RFID system consists of three main elements:

- RFID Tags (Transponders) – attached to objects and containing unique identifiers and data

- RFID Readers (Interrogators) – devices that emit radio signals and receive tag responses

- Backend Software – systems that process, store, and analyze collected data

Types of RFID Tags

RFID tags are generally classified into three categories:

- Passive RFID Tags – powered by the reader’s signal, low cost, limited range

- Active RFID Tags – battery-powered, longer range, higher cost

- Semi-Passive (Battery-Assisted) Tags – combine features of both types

Frequency Bands

RFID systems operate across different frequency ranges, each suited to specific use cases:

- LF (Low Frequency) – animal tracking, access control

- HF (High Frequency, 13.56 MHz) – NFC, smart cards, payments

- UHF (Ultra High Frequency) – logistics, warehouse management, retail

Evolution of RFID Over Time

Standardization and Global Adoption

The development of international standards, such as ISO/IEC and EPCglobal, played a crucial role in RFID’s widespread adoption. These standards ensured interoperability between devices from different manufacturers and enabled global supply chain integration.

Cost Reduction and Miniaturization

As production volumes increased, the cost of RFID tags dropped dramatically. What once cost several dollars per tag can now cost just a few cents, making large-scale deployments economically viable.

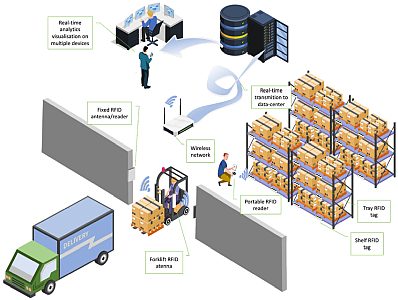

Integration with IT Systems

Modern RFID systems are no longer standalone solutions. They integrate with:

- ERP systems

- Warehouse Management Systems (WMS)

- Manufacturing Execution Systems (MES)

- Cloud platforms and analytics tools

Benefits of RFID for Tracking and Inventory Management

Accuracy and Automation

RFID significantly reduces human error in inventory processes. Unlike manual barcode scanning, RFID enables automated, bulk reading of items without physical contact.

Real-Time Visibility

Organizations gain real-time insight into the location and status of assets, improving decision-making and operational efficiency.

Reduced Labor Costs

Automated identification reduces the need for manual counting and scanning, freeing staff to focus on higher-value tasks.

Improved Security and Loss Prevention

RFID helps detect unauthorized movement of goods, reducing theft and shrinkage in retail and logistics environments.

RFID in Industry and Manufacturing

Industry 4.0 and Smart Factories

In modern manufacturing, RFID enables real-time tracking of materials, work-in-progress items, and finished products. This supports just-in-time production, predictive maintenance, and quality control.

Asset Tracking and Maintenance

RFID tags attached to tools and machinery allow companies to monitor usage, maintenance schedules, and lifecycle status.

Harsh Environment Applications

Industrial-grade RFID tags are designed to withstand extreme temperatures, vibration, dust, and moisture, making them suitable for heavy industry and outdoor use.

RFID in Transport and Logistics

Supply Chain Transparency

RFID provides end-to-end visibility across the supply chain, from production to delivery. Logistics providers can track shipments in real time and respond quickly to disruptions.

Warehouse Automation

RFID-enabled warehouses benefit from faster receiving, picking, and shipping processes, reducing errors and improving throughput.

Public Transport and Mobility

RFID is widely used in ticketing systems, toll collection, and fleet management, enabling seamless and contactless travel experiences.

RFID in Healthcare

Patient Safety and Identification

RFID wristbands help ensure correct patient identification, reducing medical errors and improving care quality.

Equipment and Asset Management

Hospitals use RFID to track medical equipment, ensuring availability and reducing losses.

Pharmaceutical Tracking

RFID supports drug authentication and cold chain monitoring, improving patient safety and regulatory compliance.

RFID in Everyday Life: Home, Sports, and Wellness

Smart Homes and Access Control

RFID cards and tags are commonly used for door access, alarm systems, and smart home automation.

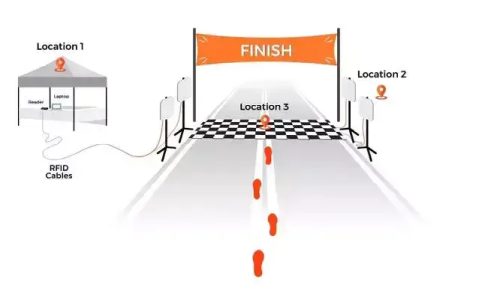

Sports and Fitness

RFID timing systems are widely used in marathons, triathlons, and other sporting events to track performance accurately.

Health and Personal Monitoring

Wearable devices using RFID and NFC technologies enable personal health monitoring and wellness tracking.

RFID vs. Other Identification Technologies

RFID vs QR Code: Identification Technology Comparison

While barcodes are cheaper, RFID offers greater automation, durability, and data capacity.

| Feature |

RFID |

QR Code |

| Technology Type |

Radio frequency identification using radio waves |

Optical identification using camera scanning |

| Line of Sight Required |

No – tags can be read through packaging or materials |

Yes – QR code must be visible and well lit |

| Reading Speed |

Very fast – multiple tags read simultaneously |

Slow – one code scanned at a time |

| Automation Capability |

High – fully automated, hands-free operation |

Low – manual scanning required |

| Reading Distance |

From a few centimeters up to several meters |

Very short – typically 10–50 cm |

| Data Capacity |

Medium to high, read/write supported |

Limited, static data only |

| Durability |

High – resistant to dirt, moisture, and damage |

Low – easily damaged or unreadable if scratched |

| Security |

Medium to high – encryption and authentication possible |

Low – easy to copy or replicate |

| Simultaneous Reading |

Yes – bulk reading supported |

No – one QR code at a time |

| Cost per Tag / Code |

Higher, but decreasing with mass adoption |

Very low – printable on paper |

| Typical Devices |

RFID readers, antennas, industrial gateways |

Smartphones, cameras, handheld scanners |

| Main Use Cases |

Logistics, manufacturing, access control, asset tracking |

Marketing, ticketing, basic identification, URLs |

While QR codes are inexpensive and easy to deploy, they are best suited for simple, manual identification tasks. RFID, on the other hand, enables high-speed, automated, and large-scale identification, making it the preferred choice for industrial, logistics, and enterprise applications.

RFID vs NFC: What Is the Difference?

NFC is a subset of RFID optimized for short-range, secure communication, commonly used in payments and smartphones.

| Feature |

RFID |

NFC |

| Technology Scope |

Broad technology family |

Subset of RFID (HF 13.56 MHz) |

| Typical Range |

From a few centimeters up to 10+ meters |

Very short range (up to 4 cm) |

| Communication Type |

Mostly one-way (tag to reader) |

Two-way (peer-to-peer possible) |

| Security Level |

Medium to high (depends on implementation) |

High – designed for secure transactions |

| Typical Devices |

Industrial readers, gateways, antennas |

Smartphones, payment terminals |

| Simultaneous Tag Reading |

Yes |

No |

| Power Source |

Passive, semi-passive, or active |

Passive (powered by reader) |

| Main Applications |

Inventory tracking, logistics, asset management |

Payments, access cards, mobile pairing |

| Integration with Smartphones |

Limited |

Native support on most modern phones |

The Future of RFID Technology

Integration with IoT and AI

RFID data combined with IoT sensors and artificial intelligence enables predictive analytics, automation, and intelligent decision-making.

Digital Twins and Smart Assets

RFID will play a key role in creating digital representations of physical assets, supporting advanced simulation and optimization.

Sustainability and Eco-Friendly RFID

Future developments focus on biodegradable tags, energy-efficient systems, and reduced electronic waste.

Security and Privacy Enhancements

Advancements in encryption and authentication aim to address privacy concerns and protect sensitive data.

Conclusion

RFID technology has evolved from a military experiment into a cornerstone of modern digital infrastructure. Its ability to provide automated, accurate, and real-time identification makes it indispensable across industry, transport, healthcare, and everyday life. As RFID continues to integrate with IoT, AI, and smart systems, its importance will only grow, shaping a more connected, efficient, and intelligent world.